Comprendre GS1 et comment SCRIBOS peut vous aider à respecter le standard

What is GS1?

GS1 is a non-profit organisation responsible for setting global standards for product identification, primarily through the use of barcodes. With a network spanning 115 national organizations, such as GS1 Germany and GS1 France, GS1 ensures that every product can have a unique barcode. These barcodes, primarily the EAN-13 codes, allow for seamless identification and tracking of products across the supply chain.

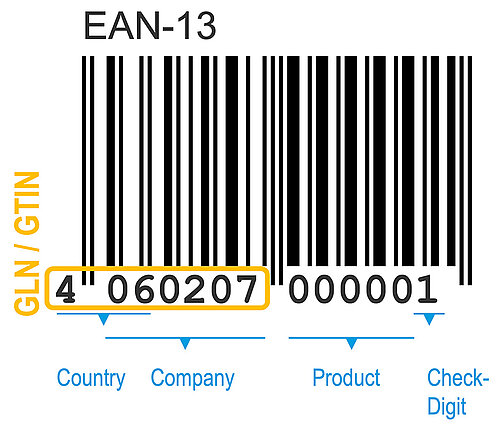

The core component of GS1’s system is the Global Trade Item Number (GTIN), which serves as the foundation for encoding barcodes. For example, an EAN barcode like 4060207000001 can break down as follows:

- 406 refers to the country (Germany in this case)

- 0207 refers to the manufacturer (Leonhard KURZ)

- 00000 represents the product

- 1 is the check digit, used for error detection

In addition to these services, GS1 also provides several tools, such as a check-digit calculator, barcode encoders and RFID services, ensuring that businesses worldwide can utilise standardised, reliable identification methods.

GS1 and the Development of Product Identification

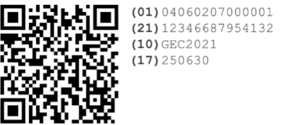

The history of GS1 is tied closely to the development of barcodes. Since the introduction of the first barcodes in the 1970s, GS1 has driven innovation in product identification technologies. In 1994, GS1 expanded beyond linear barcodes by introducing the DataMatrix. This 2D barcode system revolutionized how data could be stored in barcodes, offering several advantages over traditional linear codes:

- Space Efficiency: DataMatrix codes could store more information in a smaller space.

- Error Correction: These codes had built-in redundancy, making them readable even if partially damaged.

- Additional Data: They could store more than just the GTIN, incorporating details such as batch numbers or expiration dates.

Among 2D codes, QR codes gained popularity more quickly due to their ability to trigger direct actions, such as opening URLs, which made them particularly user-friendly. This ease of use, combined with their ability to store and direct users to websites, helped QR codes achieve mainstream acceptance. Meanwhile, DataMatrix codes became more specialized, finding a niche in logistics and encoding complex data strings.

A key factor in QR codes’ dominance has been the native support provided by smartphone camera apps from Apple and Android, which can scan QR codes directly but not DataMatrix codes. Although third-party apps exist that can read all barcodes, the lack of native support remains a significant barrier to DataMatrix adoption.

Further pushing QR codes ahead, GS1 introduced a specification for GS1-compliant QR codes in 2018, designed to deliver many of the same benefits as DataMatrix codes while being easier to use with smartphones. Although GS1 QR codes (Digital Link) are not yet universally accepted, they have been gaining momentum, particularly in the post-pandemic era when QR codes became ubiquitous in everyday life.

In comparison, GS1 DataMatrix codes remain far less visible, leaving the hope of their widespread acceptance unfulfilled. While the focus is increasingly on GS1 QR codes to achieve this level of ubiquity, the struggle for DataMatrix codes to find similar everyday relevance continues.

About GS1 Project Sunrise 2027

Recognizing the growing importance of 2D barcodes, GS1 USA launched the Sunrise 2027 initiative to encourage the widespread adoption of 2D barcodes by 2027. This effort is part of a global movement aimed at transforming how retailers and manufacturers track and identify products, with significant potential benefits on a global scale. The initiative’s primary objective is to ensure that by the end of 2027, point-of-sale systems worldwide are equipped with scanners capable of reading both traditional 1D and modern 2D barcodes. This shift is expected to deliver key advantages, including improved traceability, enhanced consumer engagement, and access to richer product information.

Although the initiative is non-binding, GS1 strongly recommends companies transition to 2D barcodes by 2028. Businesses will retain the option to use 1D barcodes after this date, but 2D barcodes provide greater flexibility and offer additional benefits. Despite this, scepticism persists due to concerns about the costs associated with upgrading to 2D barcode systems and doubts about whether 2D scanners can match the speed of current 1D laser-based systems. Additionally, uncertainty remains over which major retailers will fully commit to updating their POS systems with 2D scanners by the 2028 target.

Meanwhile, a competing initiative, Holy Grail 2.0, is exploring a different approach by embedding EAN codes as watermarks or fingerprints directly into product packaging through the printing process. This method offers a distinct advantage: the watermark is distributed invisibly across the entire surface of the packaging, allowing it to be scanned from any angle, much like traditional 1D barcodes. Because the code is spread across the packaging, it is also more resistant to damage, making it particularly useful in recycling processes where camera systems rely on the embedded codes to sort materials. Early trials under the Holy Grail 2.0 initiative have shown promising results, further highlighting its potential.

SCRIBOS and GS1-Compliant Solutions

As the GS1 system evolves, companies will need pioneers like SCRIBOS, who can help them implement GS1-compliant barcoding solutions. With over 17 years of experience printing unique, serialised GS1-compliant DataMatrix codes, SCRIBOS is perfectly positioned to help businesses transition to next-generation barcode systems, including QR codes, GS1 compliant DataMatrix and GS1 Digital Link QR codes.

- Unified GTIN Labels

SCRIBOS offers a solution that applies the same GTIN (Global Trade Item Number) across multiple products / SKUs, typically with a unique serial number for each package / label. This “Unified GTIN” approach is used in industries like automotive, where the same GTIN is applied to all items within a category, simplifying production and logistics of these security codes/labels. Because this approach incorporates a unified GTIN in the 2D QR code, the 1D EAN-13 barcode is needed to retrieve the corresponding product code

However, this setup may encounter challenges by 2028. As more checkout systems shift to QR codes for product identification, GS1 standards will increasingly require each product type to carry a GTIN, corresponding to its 1D EAN-13 product code. If different SKUs continue to share the same GTIN, systems will be unable to differentiate between distinct products. Currently, an additional EAN-13 barcode is typically printed alongside the QR code to help identify the product at checkout. But if retailers start exclusively reading GTINs from QR codes and discontinue using the EAN-13, the practice of using a unified GTIN could result in scanning errors and GS1 non-compliance.

To future-proof against this, SCRIBOS’ solution can assign unique GTINs to each product type, ensuring that QR codes remain compliant and can distinguish between different items at the point of sale.

- Direct Print for Unique GTINs

To meet GS1’s requirements for unique GTINs per SKU or product type, SCRIBOS provides a “Direct Print” solution. With this approach, each SKU is assigned its own GTIN, which is embedded directly in the QR code. This ensures that each product type has a unique identifier, fully meeting GS1 compliance.

In this model, manufacturers or print service providers can download specific QR codes directly from the SCRIBOS B2B platform, each containing a GTIN tailored to a particular product type. For example, if a winery is producing a “2025 Bordeaux Sauvignon Blanc,” they would receive / download a QR code that includes a GTIN uniquely assigned to this specific wine from our B2B platform. This code is then printed directly onto each bottle’s label.

This “Direct Print” solution is ideal for such cases, as it allows the winery to print the correct GTIN on demand during the label printing process, rather than managing a large inventory of pre-printed labels with different GTINs. As each “2025 Bordeaux Sauvignon Blanc” label is printed with its specific GTIN, the product is accurately identified at checkout, fully meeting GS1 compliance standards.

Furthermore, by generating each label as needed, the winery reduces logistical complexity and storage needs, avoiding the stockpiling of various pre-printed labels. This approach also allows for easy serialisation, where each bottle of “2025 Bordeaux Sauvignon Blanc” can receive a unique serial number alongside the GTIN, enhancing traceability and aligning with GS1 recommendations for individual package identification.

Emphasizing the Value of Serialisation

As the industry shifts away from the 1D EAN code, a static QR code – without serialised, unique ID - containing only the GTIN could be sufficient for simple product / SKU identification at POS. This basic approach does not require extensive setup for creating and printing, as a single static GTIN or code can be printed across all packages of one SKU through standard printing techniques like Flexo or Offset. However, a “static GTIN” does not mean that the entire code must be static. Here, it is important to differentiate between different approaches:

(A) Entirely Static QR Code: In this case, the QR code is static without unique IDs, essentially replacing the 1D EAN-13 code with a 2D QR code. However, each product would still require a distinct static QR code since the SKU or product number is encoded within the QR.

This can be combined with serialisation, allowing the addition of unique IDs even with a static GTIN. This leads to two versions:

- (B1) Unique GTINs with Unique IDs: This version follows GS1’s model, where each SKU has its unique GTIN and is serialised for individual tracking.

- (B2) Unified GTIN with Unique IDs: This version allows the same unified GTIN to be applied across all products, while adding serialisation through unique IDs. This can be used as long as the GTIN is still present as a 1D EAN-13 code on the product, where the product GTIN can be read from. The advantage of such a solution is that the GS1 compliant QR code can be pre-printed and applied as a(n) (extra) label – the same for all products. This saves a lot of cost and complexity in production.

While the printing aspect may seem straightforward, interpreting and managing QR code scans requires backend systems to process the data and respond to scan requests correctly. This cannot be achieved without support. Even for GS1 Digital Links with unified GTIN and non-serialised IDs, the SCRIBOS 260 platform can be used to allow businesses to track the origin of scans, display product information and integrate promotional buttons to enhance consumer engagement. SCRIBOS 360 acts as a comprehensive digital platform that integrates seamlessly with all physical and printed security solutions. It serves as a centralized dashboard for brand owners, offering real-time monitoring of scans, detection of counterfeiting hotspots and prevention of grey market activities and unauthorised overproduction.

Moreover, serialisation adds significant value in terms of security and transparency, which GS1 also recommends to improve product traceability and authenticity. SCRIBOS stands out in this area with its UniQR® solution for serialisation and its ValiGate® solution for brand protection, offering a multi-level approach to product identification and authentication.

With regulations like the EU’s Digital Product Passport (DPP) coming into effect, businesses will need to digitally provide essential product information, such as sustainability, material composition and recyclability, primarily for consumers. Unlike GS1, the DPP doesn’t specify a standard format for data storage, allowing businesses flexibility to create QR codes tailored to their needs — without paying GS1 fees for GTINs. However, as previously noted, integrating both systems offers a practical advantage; SCRIBOS offers a solution that integrates both GS1 and DPP standards into a single QR code, meeting EU DPP requirements while also supporting point-of-sale scanning as a replacement for the 1D EAN-13 barcode by GS1 compliant QR codes. This approach minimizes the need for multiple codes on a single product, ensuring smooth functionality at checkout while delivering the comprehensive product information that consumers and regulatory standards increasingly demands.

Experience in Digital Links

With over seventeen years of experience in printing GS1-compliant codes and over six years of experience in printing GS1-compliant QR codes, SCRIBOS is an expert in the new GS1 Digital Link system. While scanning a QR code can provide consumers with product details and marketing content, the primary function of these codes is to read the product code itself (similar to EAN), targeting point-of-sale and logistics chains. GS1 outlines that this functionality is possible, but does not directly provide or recommend systems to handle this process. This is where SCRIBOS offers a complete solution: not only do we assist with creating, printing, and delivering these codes, but we also provide the IT systems – such as SCRIBOS 360 – that manage scan responses, consumer engagement and product information. Therefore, we don’t just cover the technical aspect of the QR code; we enable businesses to engage with their customers at every level.

Conclusion

In conclusion, GS1 has played a pivotal role in the evolution of product identification, from the introduction of the linear barcode to the current push for widespread adoption of 2D barcodes. As initiatives like Sunrise 2027 take shape, businesses will need to adapt to more advanced identification systems to enhance traceability, consumer engagement and overall supply chain efficiency. The transition from traditional 1D barcodes to 2D systems such as QR and DataMatrix codes offers opportunities for more detailed product information and interactive consumer experiences, though it also presents challenges such as cost and infrastructure changes.

SCRIBOS is uniquely positioned to help businesses navigate these changes with confidence. With over 17 years of experience in GS1-compliant technologies, SCRIBOS provides comprehensive solutions, including labels that combine a unified GTIN with unique serial IDs for each item, thereby enhancing product traceability and security. Our expertise also extends to advanced technologies like GS1 Digital Links, allowing businesses to engage consumers directly through digital interactions, and ValiGate®, which offers an extra layer of brand protection and product authentication.

Additionally, SCRIBOS 360, our innovative digital platform, integrates seamlessly with all of our physical and printed security solutions, offering a unified brand protection solution. It enables businesses to monitor every scan and gain real-time insights, detecting counterfeit hotspots, grey market activities and unauthorised overproduction. Beyond brand protection, SCRIBOS 360 enhances customer engagement, product traceability and provides valuable market insights. This ensures that businesses not only protect their products but also maximize their connection with consumers through enhanced product interaction.

Whether you need advice or a tailored solution, SCRIBOS is the ideal partner for driving your company forward in the evolving world of product identification.